Cutting & Deburring Of Wire & Hypotube

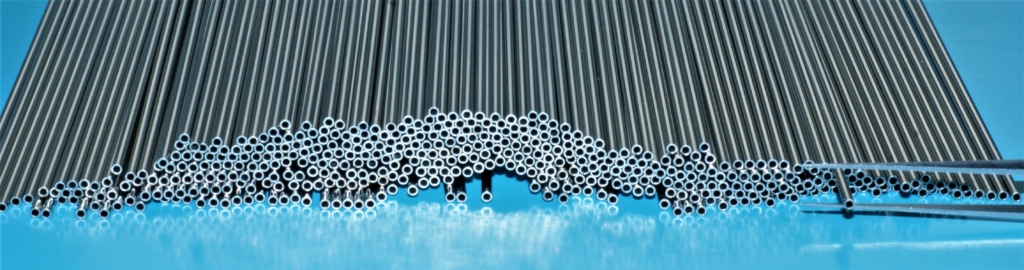

Precision Wire And Hypotube Components

Precision stainless steel wires and hypotubes are straightened, cut and deburred ready for subsequent centreless grinding to a smaller finished diameter or for final cleaning and inspection. We are able to straighten, cut and deburr wires and tubes as small as 0.3mm diameter. Our wire straightening and wire cutting capability extends to tungsten wire, molybdenum wire and other nickel-based alloys such as Monel 400 wire, Inconel wire and Nickel wire itself.

Wireforms, including springs, wire coils and continuous coils of microwire can be produced from stainless steels, tungsten wire and other exotic alloys.

Starting with coiled or spooled wire or hypotube, the product is fed through our rotary straighteners before being precision cut to a pre-determined length.

Deburring either to a chamfered or rounded end is then carried out, resulting in a product which can be reliably used without risk of sharps when placed into polymer or softer material sheaths.

Deburred wires and hypotubes can be prepared for injection moulding by abrasive blasting a “key” on the wire or tube surface. We can also PTFE coat wires and tubes, ready for applications requiring an hard-wearing, lubricious coating.

We can angle cut and laser cut hypotubes and wires. Thin wall tubes are also processed by laser cutting to produce sophisticated needles, probes and other medical delivery devices. Marker bands are laser cut from platinum iridium, gold and tantalum microtubes.