Wire and wire-forms

Precision Mandrels, Wires and Tube Components for Medical Devices

We process precision wire and rod made from a wide range of metals and alloys. Our key processes, starting with drawn wire supplied on spools, are wire straightening, wire cutting, wire forming, wire coiling and laser welding wire as part of a laser welded assembly. Continuous coils are wound from round or flat wire. Shaped wire is drawn through a die, including shaped wire from grade 9 titanium.

Materials

We work with the following materials: austenitic grade AISI 304, AISI 302, AISI 304V, AISI 316 stainless steel wire, tungsten wire, nitinol wire, titanium wire and nickel alloy wire. 304V stainless steel wire is mainly used for mandrels and as braid wire for catheter reinforcement.

Our raw materials are sourced from reliable, long term partners and are accompanied by certification of chemical and mechanical properties.

Forms & Shapes

We manufacture wire products in the following forms and shapes, as small as 0.2mm diameter and as large as 12mm diameter.

Straight, cut wire pieces – key products are mandrels, pins, guide wires, probes, shafts, activators. After straightening and cutting, we can centreless grind wire pieces as long as 3 metres to confer exceptional surface quality and diameter tolerances to +/- 2 microns. Subsequent sliding head machining of straight ground rods is also used to produce highly accurate shafts, pins, activator rods, EDM electrodes and other components for medical devices, activator systems and other specialist mechanical applications.

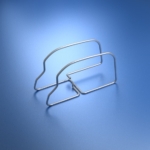

Wireforms

Numerous applications for formed wires in the medical device industry as clips, mandrels, hooks, circlips and pull-wires for catheter systems. Nitinol wires can be “shape-set” by thermal treatment to a specific configuration.

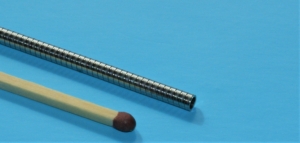

Coils, continuous, micro-coils

These are used for their flexibility both as springs and as flexible conduit within the medical device industry. Garter springs and other micro-springs are supplied. Micro-coils made from flat wire are supplied to provide thin wall and additional flexibility or rigidity depending on customer requirements. Catheter delivery systems require additional rigidity which is conferred by coiled wire. The use of braided wire is an alternative. Stranded fine wires are also supplied.

Laser welded wire forms and laser welded coils

Overlapping wires which are part of a formed wire component can be laser welded in order to induce extra rigidity and improve tolerances in making the part. Laser welded joins between coils can be used to induce additional rigidity, specifically in the region of the laser join.

Flat wire

The two methods of manufacture are firstly by flattening round drawn wire, which gives rounded corners and edges to the flat wire, or secondly by slitting the flat wire from metal foil. Slitting offers the opportunity for higher width to thickness ratios for the final flat wire.

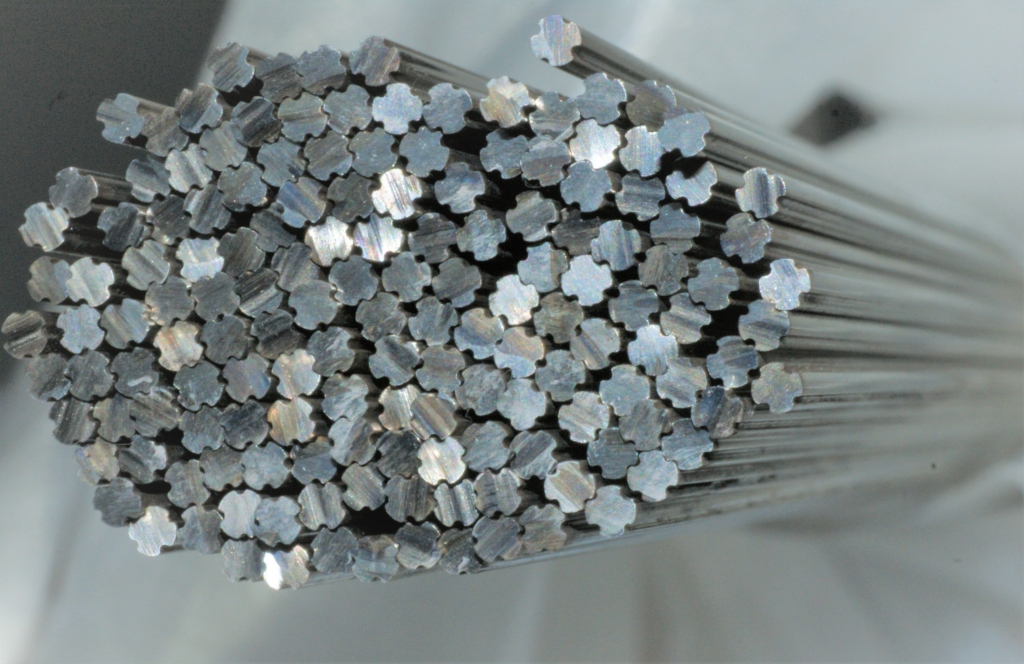

Grooved mandrels

As an alternative to die-drawing a wire or rod along its total length, we can machine one or more narrow grooves along part of the rod. This provides additional leeway in design of catheter delivery systems.

Applications

A summary of applications for our wire and rod is as follows:

Mandrels, packaging mandrels, guide wires.

Orthodontic, probes, shape setting, pull-wires

Continuous coils for flexible delivery systems, electrodes, springs, micro-springs, filaments

Stranded wire for flexible yet strong conduction

Nitinol – activators, sensors, heating elements

Tungsten, molybdenum, platinum – as electrodes and for radiopaque markers

EDM wires

Centreless ground rods, for sliding head feedstock

Pins, shafts for motors and rotary instruments

Manufacturing

We can straighten and centreless grind rods from 10mm diameter to as small as 0.2mm, providing our customers with straight wires to within 1mm/mtr. We also manufacture ground-tapered rod and wire, as commonly used for catheter mandrels.

Other applications include connectors, actuators, sensors and heater filaments. Tungsten wire and molybdenum wires are used in high temperature applications such as lamps and as electrode material. Centreless ground, straight rods are used as raw materials for precision CNC machining on sliding-head machines.

We can shape-set nitinol wire, or supply nitinol wire straight, cut and ground or electropolished.

We produce wire-forms to customer specification – including coils and hooks. Whether for stainless steel micro-coils or for larger diameter springs, we’ll be pleased to help our customers with design and manufacturing considerations.

Assemblies incorporating precision wire are made by laser micro-welding or by wire crimping. Wire crimped assemblies are an attractive alternative to welded, soldered or brazed assemblies as neither heat nor additional alloy is introduced to the joint between two or more dissimilar metals.

Wire Facts And Figures:

Outside diameters supplied from .003” to 1.20”

Materials

Stainless steel grades 304, 304V, 316, 316L,

Nitinol, titanium, tungsten, platinum and gold alloys, nickel alloys including Inconel, Kovar, Hastelloy and Monel